Pharmaceutical Ampoule Liquid Filling Machine in Ampoule Bottle Washing Sterilizing Filling Sealing Production Line Supplier with CE ISO Certificate

Basic Info.

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | Field Installation, Commissioning and Training |

| Capacity | Standard/Customized; |

| Applicable Bottle | 1-30ml Glass Vial Bottle |

| Optional Configuration | Inspection, Labeling, Blistering, Cartoning |

| Process Type | Washing, Sterilizing, Filling, Stoppering, Capping |

| Filling Capacity | 100-600bpm |

| Transport Package | Wooden Package |

| Specification | 2500*2500*1300 mm - 4280*1650*2400 mm |

| Trademark | IVEN |

| Origin | China |

| HS Code | 8422303090 |

| Production Capacity | 7000~10000 PCS/H |

Product Description

Pharmaceutical Ampoule Liquid Filling Machine in Ampoule Bottle Washing Sterilizing Filling Sealing Production Line Supplier with CE ISO Certificate

Product DescriptionThe Ampoule filling production line includes vertical ultrasonic washing machine, RSM sterilizing drying machine and AGF filling and sealing The Ampoule SVP Injectable Liquid Filling Production Line includes Ultrasonic washing machine, Sterilizing tunnel, Ampoule filling and sealing machine. Its divided into washing zone, sterilizing zone, filling and sealing zone. This compact line can work together as well as independently. Compared with other manufacturers, our equipment has unique features, including overall dimension smaller, higher automation & stability, lower fault rate and maintenance cost, and etc.

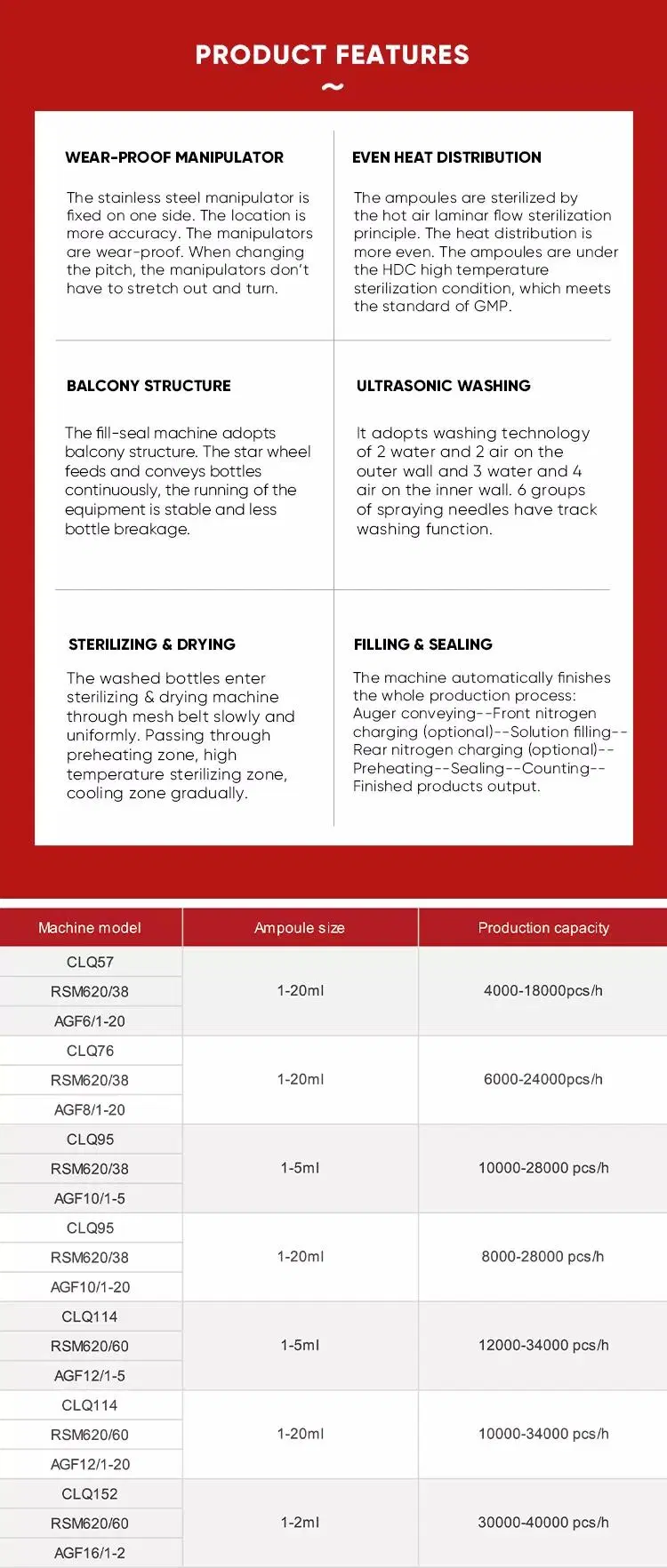

Tech Parameters

| Maximum capacity | 7,000-10,000pcs/h |

| WFI consumption | 0.2-0.3Mpa 1.0 m3/h |

| Compressed air consumption | 0.4Mpa 50 m3/h |

| Electric capacity | CLQ114Vertical ultrasonic washing machine:15.7KW |

| RSM620/60 Sterilizing and drying machine 46KW, heating power: 38KW | |

| AGF12 Ampoule filling and sealing machine 2.6KW | |

| Dimensions | CLQ114Vertical ultrasonic washing machine:2500×2500×1300mm |

| RSM620/60 Sterilizing and drying machine:4280×1650×2400mm | |

| AGF12 Ampoule filling and sealing machine:3700×1700×1380 mm | |

| Weight | CLQ114Vertical ultrasonic washing machine:2600 Kg |

| RSM620/60 Sterilizing and drying machine:4200 Kg | |

| AGF12 Ampoule filling and sealing machine:2600 Kg |

Standard washing process

Bottle sprayingUltrasonic pre-washingRecycled water: inside washing, outside washing

Compressed air: inside blowing

Recycled water: inside washing, outside washing

Compressed air: inside blowing

WFI: inside washing

Compressed air: inside blowing, outside blowing

Compressed air: inside blowing, outside blowing

1. Where have you exported your equipment?We've already exported to more than 45+ countries in Aisa, Europe, Middle East, Africa, South America,etc.2. Can you arrange the visit to your user?Yes. We can invite you to visit our turnkey projects in Indonesia, Vietnam, Uzbekistan, Tanzania etc.3. Can you customize the machine according to our requirements?Yes.4. Is your equipment in accordance with GMP, FDA, WHO?Yes, we will design and manufacture the equipment according to the requirement of GMP/FDA/WHO in your country.5. What is your payment terms?Generally, TT or irrevocable L/C at sight.6. How about your after-sales service?We will reply you within 24 hours by email or phone.If we have local agent, we will arrange him to your site within 24 hours to assist you to shoot the problem.7. How about the staff training?Normally, we will train your staffs during the installation in your site; you are also welcome to send your staff train in our factory.8. How many coutries have you done the Turnkey Project?Russia, Nigeria, Tanzania, Ethiopia, Saudi Arabia , Uzbekistan, Tajikistan, Indonesia, Vietnam, Thailand, Myanmar etc.9. How long will the turnkey project take?About 1 year from designing the layout to finish installation and commissioning.10. Which kind of after-sales service you can offer?Except the regular service, we can also provide you know-how transfer, and dispatch our qualified engineers to help you run the factory up to 6-12 months.11. What should we prepare for setting up IV plant basically?Please prepare the land, building construction, water, electricity, etc.12. What kind of certificate you have?We have ISO, CE certificate, etc.