10ml

Basic Info.

| Model NO. | LP-200E |

| Automatic Grade | Automatic |

| Structure | Linear |

| Packaging | Bottle |

| Packaging Material | Plastic |

| Air Source | 0.6-0.8MPa |

| Transport Package | Wooden Case |

| Specification | 3540*1800*1800mm(L*W*H) |

| Trademark | Jinwang |

| Origin | Jiangsu, China |

| HS Code | 8428399000 |

| Production Capacity | 10 Set/Month |

Packaging & Delivery

Package Size 2800.00cm * 1500.00cm * 1650.00cm Package Gross Weight 950.000kgProduct Description

10ML-1L Automatic High Speed Round Plastic Bottle Sorting Unscrambler

Product Description

Introduction

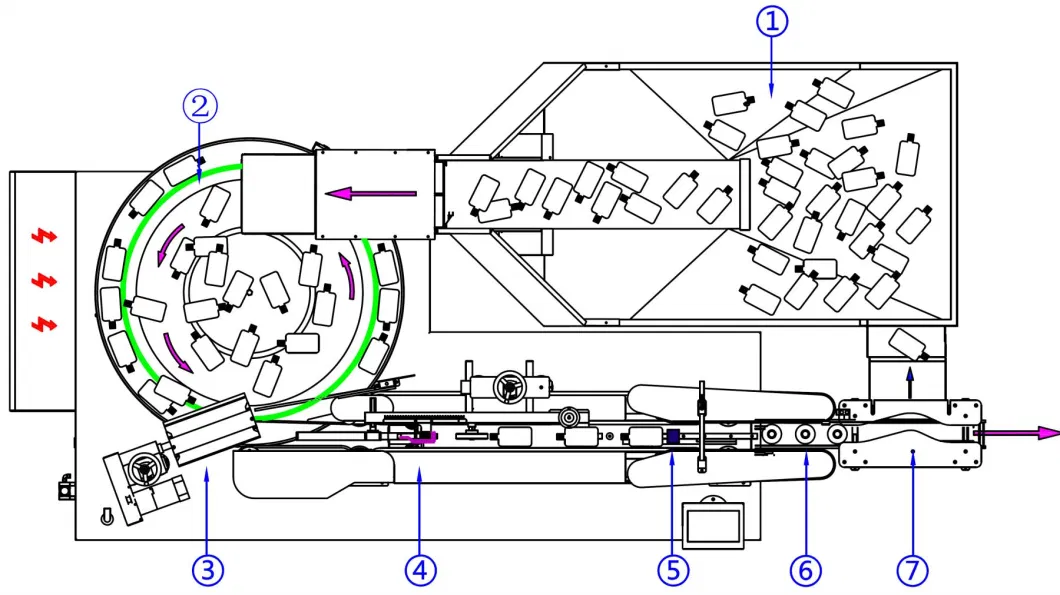

LP-200E Automatic Bottle Unscrambler is making up of the bottle bucket, unscrambling plate , bottle reject opponent, bottle-stand-up hook, air rejection device, and detection device as well as the electric cabinet.It is applied to the bottle unscrambling of plastic round and flat bottle. When putting the disordered bottle into the bottle holder, through the unscrambling plate, then the bottles will stand in the filling line in order. The machine has the features of simple structure, easy operation and good stability. It can reduce the labor force. For now it has been widely used in agro chemical industry

Product Parameters

Technical Parameters

| 1 | Unscrambling Speed | 50ml:200bottles per minute;250ml:150bottles per minute; 1000ml:110bottles per minute *speed will be affected by the bottle size, bottle material |

| 2 | Bottle Diameter | Round Bottle:Φ40-95mm Bottle Height 80-240mm |

| 3 | Air Source | 0.6-0.8MPa |

| 4 | Power Source | ~220V 50Hz/2.5KW |

| 5 | External Dimension(Bottle Unscrambler) | 3540×1800×1800mm(L×W×H) |

| 6 | External Dimension(without bottle Elevator) | 2730×1450×1500mm(L×W×H) |

| 7 | Weight | ~ 900Kg |

Bottle Applications

Widely used in pesticides, veterinary drugs, fine chemicals, daily chemicals, fertilizers, oils and other industries

Process Flow

- Bottle loading (bottle enters the bottle unscrambler turntable through the bottle loading machine)

- Bottle delivery (the round turntable sends the bottles to the unscramble station, and the belt in the turntable can be used for different bottle diameters by increasing or decreasing the belt in the turntable)

- Kick the bottle (reject the overlapping bottles to facilitate bottle sorting)

- Hook bottle (use the bottle hook device to stand the bottle hook upright with the bottle mouth facing forward)

- Stand up the bottle (use the bottle stand up mechanism to erect the bottle with the bottom of the bottle facing forward)

- Bottle Feeding out(the upright bottle is transported to the filling station through the conveyor belt)

- Rejection of inverted bottles (detection of inverted bottles through photoelectric, and automatic rejection of inverted bottles into the upper bottle hopper by the mechanical inverting device)

Advanced Features

- The structure is compact, the floor space is small, the whole machine is simple, with only three operation buttons, the operation is simple, and it can be completed by one button.

- When changing different bottle size, you do not need to change anything, you only need to change the belt in the bottle hopper and adjust the space of the unscrambling structure. And it is applied to 50-1000ml bottle.

- Automatic bottle elevating function, you only need to put the bottles in the bottle elevator, a sensor is installed in the rotary plate, it will automatically elevates the bottles when there is not enough bottle, it will start when the bottles are enough consequently.

6. Equipped with inverted bottle removal device, when bottle fall down, the photoelectric sensor will detects the inverted bottles, it will kicks the bottle back to the bottle collection bucket, without human intervention.

Application Scenario

Company Profile

Jiangsu Jinwang Intelligent Sci-Tech Co., Ltd (JWIM) established in May 2005. JWIM is a professional manufacturer engaged in agricultural and animal husbandry intelligent factory. We are a high-tech enterprise integrated with R&D, manufacturing, marketing and service.JWIM products focus on the agriculture and animal husbandry industry, so far it has obtained more than 100 patent certificates, among them JWIM intellectual formulation workshop has 8 invention patents and 8 utility model patents. The products have been exported to more than 50 countries at home and abroad. We have provided professional services to more than 3, 000 agricultural and animal husbandry customers.In order to adapt to the development of Industry 4.0 and Made in China 2025, the intellectual formulation workshop researched and developed by Jinwang is a safe, environmentally friendly, intelligent, integrated and efficient formulation workshop.Our products include intelligent processing, intelligent packaging, intelligent storage, intelligent general control and intelligent factory. Our services include operation and maintenance services (Jinwang agrochemical Business School), remote services, contracted services, service station services, integrated workshop transformation services and EPCM services for intelligent factories.We have an after-sales team of 200 service engineers, including 50 overseas after-sales service engineers, serving Vietnam, Indonesia, Thailand, Philippines and other countries all over the world. The global Internet service center can provide remote services to help customers solve problems online.

Certifications